Customer Projects

Medical-Grade Oxygen Generators for High-Altitude Communities in Peru

- Industry: Public health program (Government of Peru)

- Customer Challenge: High-altitude regions in central Peru faced severe difficulty in oxygen supply. Relying on traditional cylinder logistics involved prohibitive transportation costs and unreliable supply chains, severely hindering respiratory care and emergency support for local communities.

- Solution Delivered: Deployment of medical-grade oxygen generators designed for high-altitude environments, combined with the establishment of community oxygen stations.

- Results: Oxygen supply stability in key medical zones reached 100%. Public health expenditures on oxygen plummeted due to on-site production. Access to life-saving oxygen therapy expanded significantly.

- Customer Feedback: “These oxygen generators are essential to our communities. The equipment operates reliably, and the international support team has proven dependable.”

One-Stop Medical Oxygen Generation System for a Hospital in Venezuela

- Industry: Public healthcare (Venezuela)

- Customer Challenge: High cost and unstable supply of bottled oxygen restricted hospital capacity and affected patient treatment continuity.

- Solution Delivered: Deployment of a one-stop medical oxygen generation system to enable on-site oxygen production within the hospital.

- Results: Medical oxygen cost reduced by more than 40%. Oxygen supply stability in critical care areas reached 100%. Overall treatment efficiency improved substantially.

- Customer Feedback: “This system has become our lifeline. Operation is highly stable, and the international remote support team responds quickly and effectively.”

Industrial Oxygen System for an Aquaculture Enterprise in Saudi Arabia

- Industry: Intensive aquaculture (Saudi Arabia)

- Customer Challenge: Traditional aeration methods showed low efficiency and high energy consumption. Under high ambient temperatures, dissolved oxygen levels failed to meet requirements for high density farming, limiting yield growth.

- Solution Delivered: Deployment of a high capacity, heat-resistant industrial oxygen generation system integrated with pond aeration equipment.

- Results: Dissolved oxygen levels remained within the ideal range. Fish survival rate increased by 15%. Overall feed conversion efficiency improved noticeably.

- Customer Feedback: “This oxygen system is the cornerstone of our high-density operations. Its stable output and reliability in extreme heat have significantly reduced our per-unit energy consumption.”

Industrial Oxygen System for a Metal Smelting Plant in Myanmar

- Industry: Metal smelting (Myanmar)

- Customer Challenge: The facility previously relied on expensive, externally sourced bottled oxygen. An erratic supply chain and high procurement costs led to inconsistent furnace combustion efficiency and fluctuating product quality, making operational cost control nearly impossible.

- Solution Delivered: Deployment of a high-capacity, heat-resistant industrial oxygen generation system for on-site oxygen production.

- Results: Oxygen supply stability reached 99.5%. Fuel consumption decreased by 10%. Product oxidation rate declined. Total annual oxygen-related expenditures were slashed by over 35%.

- Customer Feedback: “This system has completely eliminated our supply chain vulnerabilities. Stable gas supply improved process performance and delivered clear cost savings.”

PSA Nitrogen Generation System for an Electronics Manufacturer in Israel

- Industry: Electronics manufacturing and SMT reflow soldering (Israel)

- Customer Challenge: The facility struggled with inconsistent purity and escalating costs of liquid nitrogen. During the reflow soldering process, unstable nitrogen quality caused severe PCB oxidation, leading to a high rate of soldering defects and compromising the integrity of high-end electronic components.

- Solution Delivered: Deployment of a high purity, low dew point PSA nitrogen generation system supplying multiple SMT lines.

- Results: Nitrogen purity remained above 99.99%. PCB oxidation defects decreased by 90%. Overall yield improved by 5%. Nitrogen cost dropped by 40%.

- Customer Feedback: “This nitrogen generator has become the guardian of our precision manufacturing process. Its exceptional stability has provided us with a measurable leap in both product quality and cost optimization.”

Food Grade High Purity Nitrogen System for a Food Manufacturer in Russia

- Industry: Food packaging and preservation (Russia)

- Customer Challenge: Conventional preservation methods failed to sufficiently reduce residual oxygen levels within packaging. As a result, sensitive products like chips and nuts suffered from rapid oxidation and moisture absorption, leading to a shortened shelf life and a high volume of market complaints regarding product quality.

- Solution Delivered: Deployment of a food-grade, high purity nitrogen system for nitrogen flushing packaging lines.

- Results: Residual oxygen levels within packaging were consistently reduced to below 1%. Product shelf life was extended by 50%. Customer complaints related to spoilage and staleness plummeted by 85%.

- Customer Feedback:“This nitrogen generator is the heart of our production line. The nitrogen flushing is exceptionally stable, effectively locking in freshness and crunch. We have seen a significant leap in customer satisfaction since its implementation.”

Customer Gallery

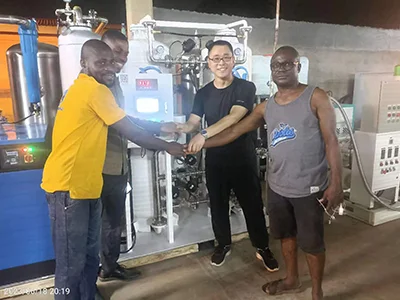

40 Nm³/h oxygen generator for Burundi customers

40 Nm³/h oxygen generator for Burundi customers Russian Customers

Russian Customers Russian Customers Inspecting Ammonia Decomposition Hydrogen Production Unit

Russian Customers Inspecting Ammonia Decomposition Hydrogen Production Unit Congo Customers

Congo Customers Ghana Customers

Ghana Customers Cameroon Customers

Cameroon Customers 10 Nm³/h Containerized Oxygen Generator for Côte d’Ivoire Customers

10 Nm³/h Containerized Oxygen Generator for Côte d’Ivoire Customers 360 Nm³/h Oxygen Generator for Myanmar Customers

360 Nm³/h Oxygen Generator for Myanmar Customers Nigeria Customers

Nigeria Customers Seychelles Customers

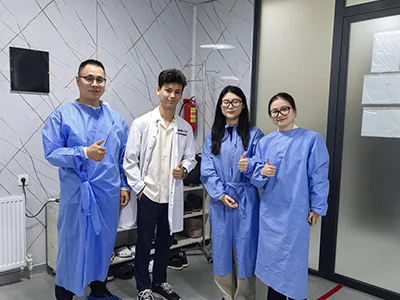

Seychelles Customers Venezuela Customers

Venezuela Customers Customer Visit: Venezuela Partnership

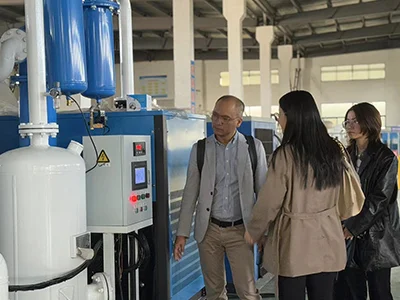

Customer Visit: Venezuela Partnership On-site Inspection in Uzbekistan and Kyrgyzstan

On-site Inspection in Uzbekistan and Kyrgyzstan Brazil: Nitrogen Generation Project Collaboration

Brazil: Nitrogen Generation Project Collaboration Customer Visit: Iraq Partnership

Customer Visit: Iraq Partnership Iran: Dosing Pump Project

Iran: Dosing Pump Project 20 Nm³/h Nitrogen Project for Iranian Customer

20 Nm³/h Nitrogen Project for Iranian Customer  India Customer: Technical Discussion

India Customer: Technical Discussion 20 Nm³/h Nitrogen Project for India Customer

20 Nm³/h Nitrogen Project for India Customer Kazakhstan Customer On-site Inspection

Kazakhstan Customer On-site Inspection

Customer Testimonials