Compressed Air Dryer

Refrigerated & desiccant compressed air dryers for nitrogen & oxygen gas generation systems

Refrigerated & desiccant compressed air dryers for nitrogen & oxygen gas generation systems

The refrigerated air dryer operates by using refrigerant to absorb heat from compressed air and reduce air temperature to a pressure dew point range of 2°C to 10°C. Compressed air entering pipelines typically contains significant amounts of water vapor, which condenses into liquid as it cools. Without effective air drying, as much as 90 liters of water can infiltrate a system daily, leading to corrosion, equipment damage, and compromised product quality.

Luoming refrigerated air dryers remove moisture efficiently and deliver dry compressed air for stable system operation. Reliable moisture control supports continuous operation and improves production efficiency. Refrigerated and desiccant dryer product lines provide multiple dew point options, enabling tailored drying solutions for compressed air systems.

Refrigerated & desiccant compressed air dryers for nitrogen & oxygen gas generation systems

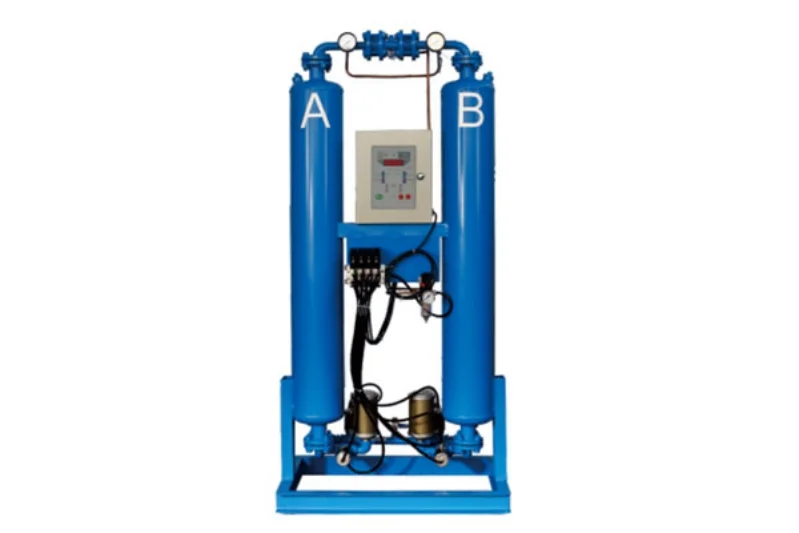

Moisture adsorption is achieved by passing compressed air through adsorption towers filled with desiccant materials such as molecular sieve or activated alumina. Water vapor is captured by the adsorbent, and dry air exits the tower.

Adsorbent regeneration restores drying performance after saturation. Pressure swing adsorption regenerates adsorbent through depressurization and moisture desorption. Temperature swing adsorption regenerates adsorbent through controlled heating to release moisture.

Alternating tower operation ensures continuous dry air supply. Dual adsorption towers operate in parallel, with one tower adsorbing moisture while the other undergoes regeneration. Continuous drying performance is maintained without interruption.