Custom Medical Oxygen Generation System

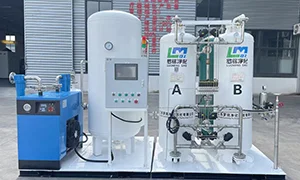

Custom-Built PSA Oxygen Generator (up to 95% Purity)

The medical PSA oxygen generator uses clean ambient air as the feed gas. Medical-grade air compressors raise air pressure to the required level, followed by refrigerated dryers, precision filters, and oil mist removers to remove moisture, dust, and oil mist, completing feed air pretreatment. Pretreated compressed air enters PSA adsorption units equipped with dual adsorption towers. Medical-grade zeolite molecular sieve preferentially adsorbs nitrogen and carbon dioxide under pressure, enriching oxygen and producing oxygen with purity up to 93%±2%. Simultaneously, the alternate adsorption tower undergoes depressurization to desorb impurities and regenerate the molecular sieve. Alternating tower operation ensures continuous oxygen output. Final-stage medical-grade sterilizing filters remove microorganisms. Pressure regulating valves adjust outlet pressure to medical requirements. Oxygen purity and pressure are monitored in real time, and emergency oxygen storage configurations support safe and stable medical oxygen supply.

- Oxygen capacity: 1-200Nm³/h (standard conditions)

- Oxygen purity: 93%±2% (per Chinese National Standard)

- Outlet pressure: 0.1-0.55MPa (gauge, stable and adjustable)

- Oxygen dew point: ≤-40°C (at atmospheric pressure)

- Feed air pretreatment for clean inlet air

Compression is performed by medical-grade air compressors at 0.6-0.8MPa to meet separation requirements.

Purification removes dust particles ≤1μm through precision filters, reduces dew point to ≤-40°C via refrigerated drying, and limits oil residue to ≤0.1mg/m³ through oil-water separation, meeting medical cleanliness standards. - PSA adsorption separation serves as the core oxygen purification process.

Dual or multi-tower operation uses medical-grade zeolite molecular sieve to preferentially adsorb nitrogen and carbon dioxide. PLC-controlled adsorption and regeneration cycles operate at 1-2 minutes per cycle.

Continuous oxygen production maintains oxygen purity at 93%±2% during adsorption while regeneration releases impurities without supply interruption. - Oxygen post-treatment ensures compliance with medical oxygen standards.

Optional secondary PSA purification produces oxygen purity above 99.5%.

Medical-grade 0.22μm sterilizing filters remove microorganisms. Pressure regulation maintains outlet pressure at 0.1-0.5MPa to match terminal requirements. - Monitoring and safety functions enable effective risk control.

Online monitoring tracks oxygen purity, pressure, and flow rate. Audible and visual alarms activate under abnormal conditions such as oxygen purity below 90%.

Emergency oxygen storage tanks or manifolds enable automatic switchover during unexpected events to ensure uninterrupted oxygen supply. - Medical performance advantages support safe and efficient clinical operation.

Safety relies on physical separation without harmful substances and low operating pressure of 0.6-0.8MPa, offering improved safety compared with high-pressure cylinders.

Efficiency supports qualified oxygen output within 30 minutes and oxygen purity up to 99.5% within 45 minutes, suitable for emergency and surgical applications.

Energy consumption remains low under ambient temperature operation, approximately 60%-70% of conventional liquid oxygen equipment, with one-button start and unattended operation support.

| Model | Oxygen purity | Flow rate (Nm³/h, standard conditions) | Inlet nominal diameter | Outlet nominal diameter | Filling pressure (MPa) |

| 93%±2% | 3 | DN15 | DN15 | 15-20 | |

| 93%±2% | 5 | DN15 | DN15 | 15-20 | |

| 93%±2% | 10 | DN25 | DN25 | 15-20 | |

| 93%±2% | 15 | DN40 | DN25 | 15-20 | |

| 93%±2% | 20 | DN40 | DN25 | 15-20 | |

| 93%±2% | 25 | DN40 | DN25 | 15-20 | |

| 93%±2% | 30 | DN40 | DN25 | 15-20 | |

| 93%±2% | 40 | DN50 | DN40 | 15-20 | |

| 93%±2% | 50 | DN50 | DN40 | 15-20 | |

| 93%±2% | 60 | DN50 | DN40 | 15-20 | |

| 93%±2% | 70 | DN65 | DN40 | 15-20 | |

| 93%±2% | 80 | DN65 | DN40 | 15-20 | |

| 93%±2% | 90 | DN65 | DN40 | 15-20 | |

| 93%±2% | 100 | DN65 | DN50 | 15-20 | |

| 93%±2% | 110 | DN65 | DN50 | 15-20 | |

| 93%±2% | 120 | DN80 | DN50 | 15-20 | |

| 93%±2% | 130 | DN80 | DN50 | 15-20 | |

| 93%±2% | 140 | DN80 | DN50 | 15-20 | |

| 93%±2% | 150 | DN100 | DN50 | 15-20 | |

| 93%±2% | 160 | DN100 | DN50 | 15-20 | |

| 93%±2% | 170 | DN100 | DN50 | 15-20 | |

| 93%±2% | 180 | DN100 | DN65 | 15-20 | |

| 93%±2% | 190 | DN100 | DN65 | 15-20 | |

| 93%±2% | 200 | DN100 | DN65 | 15-20 |